How to fix PTFE conveyor belt?

(1)PTFE Conveyor belt positioning. Use a clamp to clamp the belt to equilibrium.

(2) Treatment of the parts to be repaired. According to the shape and degree of damage of the part to be repaired, it should be trimmed and polished, and the edge of the part to be repaired should be formed as a smooth transitional slope. The intention of grinding the parts to be repaired is to remove impurities and residual glue, and improve the bonding effect. Generally, the sanding wheel of the sanding machine is used for grinding. It is necessary to pay attention to the grinding time, prevent the appearance of high-temperature carbonized rubber and damage the core cloth layer. If the scratch is deep and the canvas is injured, it is necessary to remove the damaged canvas layer as much as possible. It is necessary to ensure that the surface to be repaired has no impurities.

(3) Finishing the polished parts. Grinding will produce a large amount of rubber dust. In order not to affect the bonding force, the repairing parts are blown with a hot air blower and a brush to ensure that the surface is clean and free of dust, and does not contain grease, cleaning agents and the like. Do not use chemical cleaning agent, because the cleaning agent will penetrate into the canvas layer and will not evaporate completely in a short time. It will simply cause defects in the repair layer, especially pay attention not to wash with water.

(4) Pick up the repair strip. According to the resolution of the finishing situation, the strips are repaired with or without wires. If the core layer of the repaired parts is damaged, in principle, the clips are used to repair the strips. Cut according to the repaired area and trim the edge of the strip to match the edge of the repaired part.

(5) Drying the grinding parts of PTFE conveyor belt. Water seepage, moisture and cleaning flux in the glue layer can affect the repairing effect. Dry the repair surface with iodine tungsten lamp or hot air blower to ensure complete boring. After baking for a period of time, check whether it becomes damp. If the color changes, continue to bake. Note that the iodine tungsten lamp should be kept at a certain distance from the polished part. .

(6) Matching glue. According to the size of the repaired surface, determine the amount of glue, and according to the ratio given in the manual (the ratio of RS2002 cold glue is 1000:40), accurately weigh each cold adhesive group for compounding. Adhesives are used with the equipment. After being used, they must be used up once (within 3 to 5 minutes).

(7) Gluing and protection. Apply the glue to the repairing area and the film at least twice, and it is boring.

(8) Adhesive and curing of PTFE conveyor belt. Fit the patch film and roll it tightly. The remaining rubber edge around it is flattened with a knife.

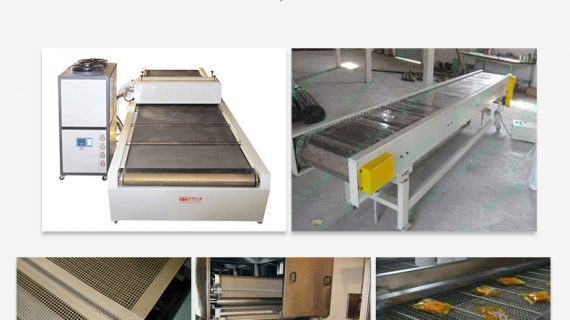

The main PTFE coatings products for China Wellflon Group such as: PTFE Glass Cloth,PTFE Glass Cloth Tape,PTFE Skived Film Adhesive Tape,PTFE Open Mesh,PTFE Conveyor Belt,PTFE Baking Sheet,PTFE Architecture Membrane. Welcome to contact us if you have regular related requirement!